Aimict Pro: A Revolutionary Enhancement for Enhanced User Experience

Addressing Functional Issues and Elevating Product Quality In AC1.2, we had successfully resolved core issues, but to maintain our competitiveness in the market, we embarked on a revolutionary upgr...

Silicone Bowl Cracking & AC 1.2

Among the 4300 devices, the silicone bowls proved to be extremely fragile when faced with the claws of actual use. This was an unexpected issue for us, as it had never occurred in the first batch o...

Under normal conditions of sand quantity and motor torque rotation, there is a possibility of the ball shell being displaced by the gears. Therefore, we conducted repeated tests and verifications f...

Insufficient Motor Torque Leading to Ball Shell Slippage

Among the 4300 users, a portion of the devices experienced ball shell slippage during rotation. This issue had not surfaced during our extended testing period, and initially, we even suspected it...

New Challenges Arise After the 4300 Deliveries, Affecting Core Functionality

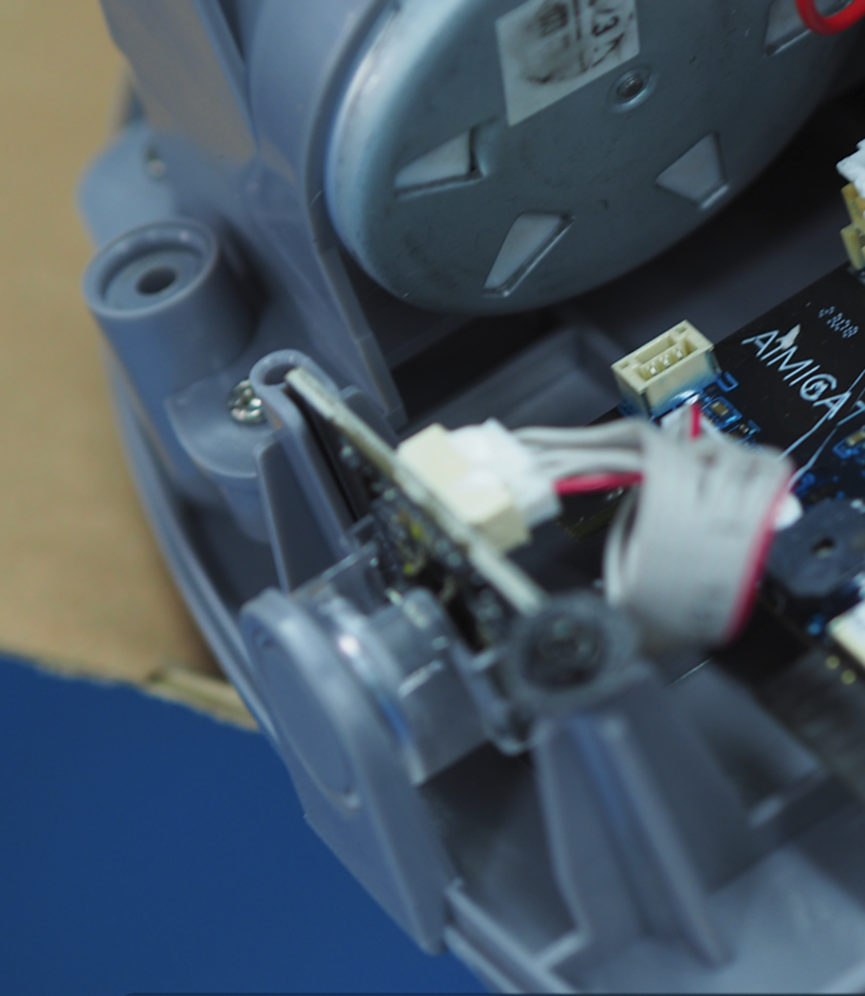

The Uncontrolled Ball Shell Rotation Caused by the Keypad Shortly after the delivery of the 4300 units, both the devices in our possession and those in the hands of users began experiencing an issu...

Development of Production Line Testing Fixtures Building upon the lessons learned from the first batch of production, we needed to design a series of testing fixtures and tools that could facili...